This is a great article written by Colin Carlu Olexa over at Fab Shop Magazine.

click the picture to be directed to the article

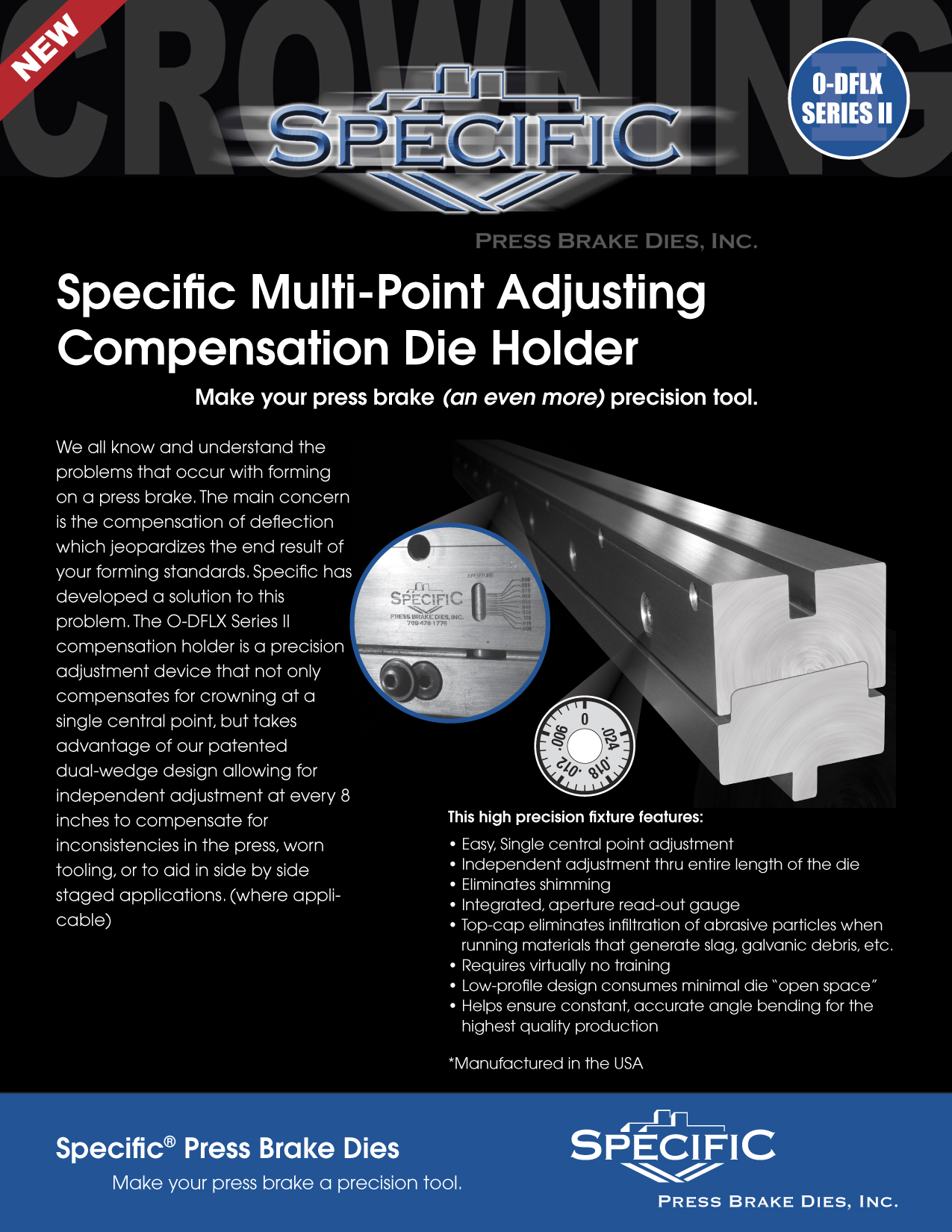

For more information regarding our Series II Multipoint Compensating die holder, please visit:

http://www.specificbrakedies.com/index.cfm/products/Compensation-Die-Holder-ii

and click here to enlarge:

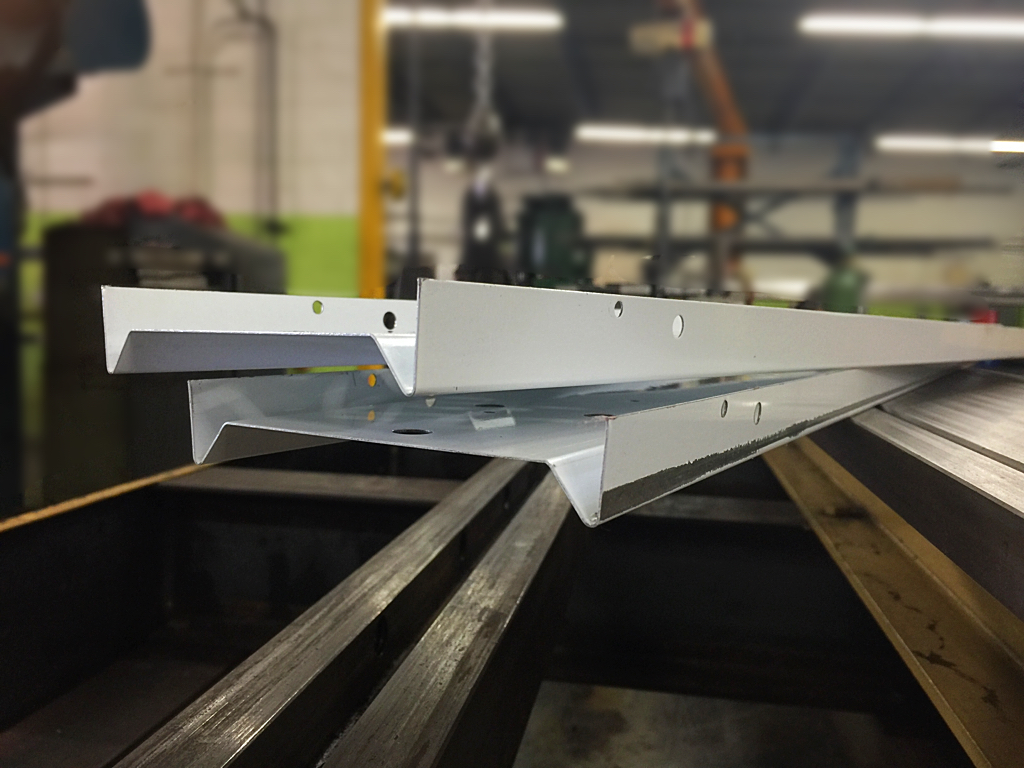

Welcome to urethane die film 101. This is the latest example of many applications that I've used our urethane die film to prove out one of our manufactured die sets. Our die makers here at Specific do what we can to ensure a quality product by polishing necessary components and specific areas of the press brake die to achieve a quality bend each and every time. However.....sometimes that just isn't enough. Below is a featured product that recently came through our shop with one of our custom forming die sets. The material is a light gauge aluminum that's been prepainted white with the show side on the outside of the part.

As you can clearly see in this picture, no matter what I did to polish the die, the white paint was just easily taken off even with the best of finishes on the tool. Now this is where the urethane die film comes in handy. Again....clearly shown in this picture, that I've achieved the same bend, with no affect on the painted surface what so ever. The proof is in the puddin!!! This stuff really does work. Think of all the time and money this has saved our customer in the long run when there is no second hand operation past the forming stage to get this part to pass inspection.

Now here are some technical specs of the urethane die film itself. Our die film comes in various widths and thickness'. The standard (clear) film is .015" & .030" thick. Even though the die film acts as a barrier between metals, the film stretches into the bend. As this stretching occurs, the urethane material breaks down to a certain extent much like a rubber band fatigues over time. This could be after 10 bends...could take 50. But over the span of 100' per roll, you have more than enough urethane to reposition and replace to get your money's worth. We also offer a heavy duty .022" thick urethane die film. It is produced of a heavier durometer urethane to last longer than our standard. At just about twice the cost, you get approx three times as many hits in comparison. You do the math.

The result: Your part can be cosmetically or physically sensitive, pre-painted, or even perforated AND bent cleanly and accurately. And in most cases, without needing to polish or grind after forming. And lets be honest, elimination of secondary operations is always a good time.

Until next time...Keep forming, my friends.